Cavity & Core work demands high performance, high accuracy tooling that are designed specifically for hard milling and high speed machining (HSM). OSG’s PHOENIX and WXS tools are designed specifically for Die/Mold applications, from roughing indexable cutters to high accuracy finishing end mills.

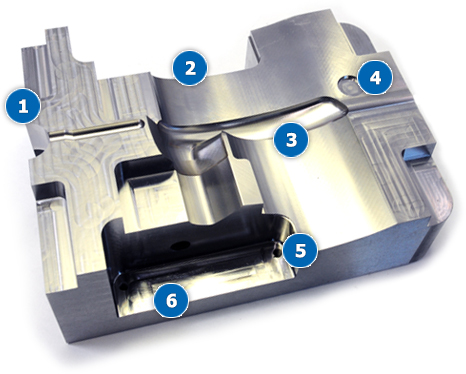

1. PHOENIX PHC END MILL & FACE MILL

PHC: High feed end mills and facemills for maximum metal removal rates in a variety of milling applications.

2. PHOENIX PFB INDEXABLE END MILL

PFB: High precision indexable finish ballnose end mills for superior surface finish and tool life.

3. WXS END MILL

WXS: Engineered for hard milling at high speeds from 54 HRC to 70 HRC.

4. WXS END MILL

WXS: Engineered for hard milling at high speeds from 54 HRC to 70 HRC.

5. WH70-DRL DRILL

WH70-DRL: Carbide drill for hardened steels from 50 HRC to 70 HRC.

6. PHOENIX PSE END MILL & FACE MILL

PSE: Multifunctional 90° indexable end mills and facemills.